Norco, CA, October 30 - QCP is here for your design, and some of our proudest work includes the custom projects we contribute to on a regular basis. From fully customized designs to modified versions of our Standard Products, there’s a wide range we work with to successfully complete each project.

To better understand how to specify us and maximize your custom project experience, we’ve outlined everything landscape architects and designers should know about working with QCP. Family owned and operated since 1976, we've dedicated nearly five decades to crafting the most durable and design-forward site furnishings.

“‘For your design’ really speaks to the whole custom part of the business,” says QCP CEO Rick Crook. “We’ve learned so many new capabilities through custom, which has led to innovations we’ve incorporated into our standard product development.”

Defining the type of project

For starters, you’ll need to know what type of custom project you’re interested in designing with our team. We categorize these different levels of customization as:

-

Group A: This involves modifying existing designs for repetitive production, so we’re reusing molds multiple times but we already have a familiarity with the design.

-

Group B: This is a project with unique but repeating elements, meaning we can reuse a mold several times before recycling it.

-

Group C: Each piece we create is unique and requires its own individual mold, which we typically only use once before recycling it for the next project.

“Some companies might only do the artistic design and others might only do custom sizing for site furnishings, but we can do everything in between,” Crook adds.

Understanding the benefits of custom projects with QCP

We’ve learned from decades of experience.

No one has done more custom work with precast concrete than our 150-person team, which has more than 40 years of experience in the industry. Through these projects, we’ve figured out how to manage small or large-scale projects, from the development stages with the landscape architect all the way through to delivery.

We prioritize the latest technology.

With the latest technology, we can now take elevations from the customer or be part of their building information modeling (BIM). This allows us to get a full picture of the assignment and ensure every part of the project works well together. Once we determine what a project needs, we create 3D models of each product and then program the mold to be built right off of those models with our CNC machine. The result? The most accurate piece possible. Because of this, we highly recommend specing QCP in the design development (DD) stage.

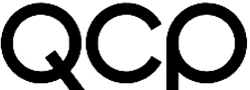

The Group C Redmond Technology Station in Redmond, Washington involved creating custom seat walls and benches with very little repetition in our mold making, which were made to look like a fallen tree. We also integrated custom wood elements and relief patterns into the concrete and stitched them all together on a bridge, which made for a more complex site.

“The vast majority of our efforts were spent with CAD and CNC and mold development to come up with the patterns,” says Marc Emery, QCP’s director of pre-construction services and estimating. “They were trying to replicate a fallen tree, and we dedicated a lot of time getting that pattern to a level of continuity.”

Always looking to innovate, we’re constantly looking into new technology that can improve our process.

We collaborate with landscape designers and architects.

When you specify QCP, you sign on for a true collaborator. Along with the technology, we verify that each of the individual pieces fit together and work within the grade. We’ve also developed strong relationships with landscape architects, which makes it easier for us to meet their high standards while also maintaining a dialogue about alternative solutions, if necessary.

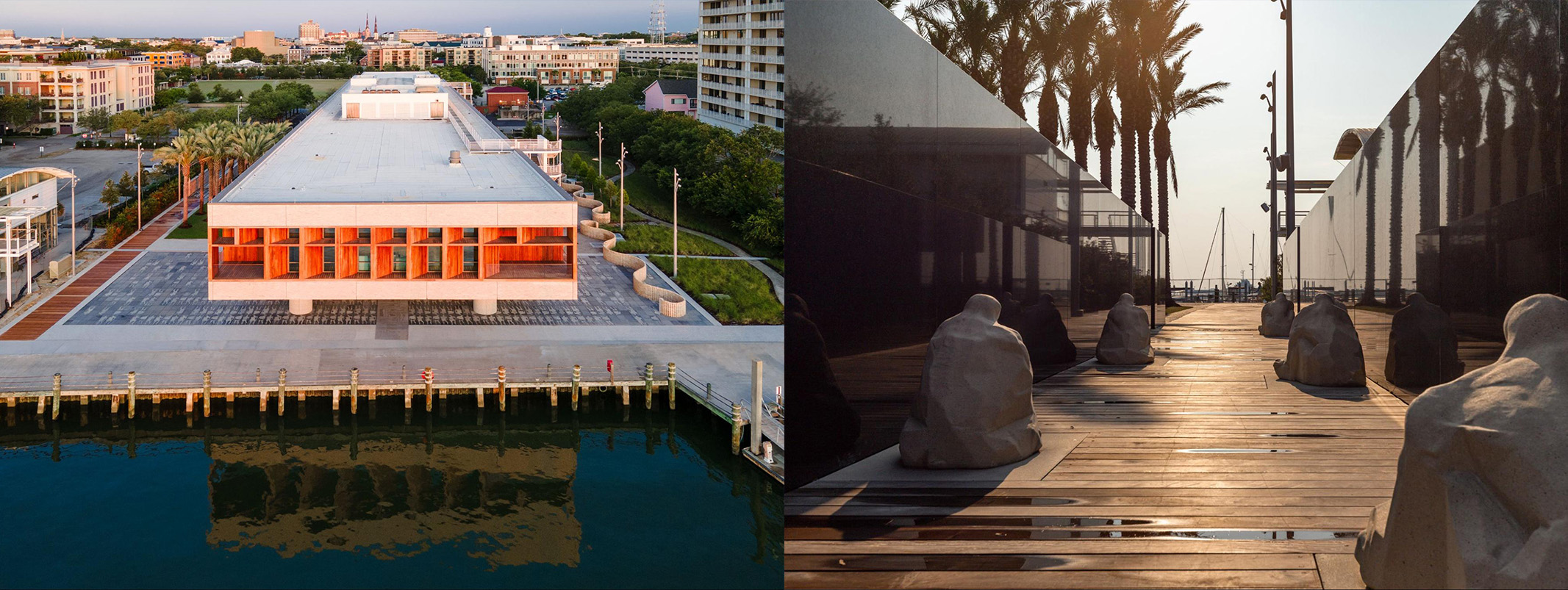

For example, when we collaborated with award-winning landscape artist Walter Hood for the International African American Museum Group C project, we became part of the artistic process by taking their clay sculptures and developing larger foam molds to fully visualize the pieces before they were sent into production.

There are other projects that aren’t quite as complex, and simply involve modifying the size or shape of our existing Standard Products — also known as Group A projects. For instance, the recently opened Fontainebleau in Las Vegas is a modified version of our Arris planters. Desiring products unlike anything else in Las Vegas, we worked with them to produce wider and taller versions. The dimensions they originally wanted were too top-heavy, so we made a suggestion to increase the size of the base.

A middle ground of these two custom examples is the Wilmington Waterfront in Los Angeles, which we categorize as a Group B project. We created custom benches, which were brand new pieces but with repeating elements.

We’ve perfected our finishes.

Our accuracy extends to our finishes and color pigments, and we’re able to match everything to your specification. In fact, some of our most popular finishes, such as etching and honing, have come from custom projects.

We can now add wood and steel elements.

The latest reason to go with QCP for custom? Mixed media. You can now incorporate wood and steel elements into practically any design. So, rather than working with separate companies for each material, you can work with us for all three — and more. We’re also experienced in sourcing other materials required for any project.

We can help with value engineering.

If your budget isn’t aligning with your vision, we can work with you to suggest other routes to take for a similar effect. “We’ve done and seen it all,” Crook says. “We know how to make things work and still keep the design intent.”

We make onsite installation easy.

We can assist with connection methods to enable the most efficient onsite installation process. This will ultimately save you time and money, lead to a high-quality result, and create a safer environment for everyone involved.

We’re more than ready to take on a challenge.

Custom is in our DNA, and it goes back to our founder Fred Crook in the early days at QCP. Never backing down from a challenge, he’d always say, “We’ll do anything.”

“There are a lot of companies that will only do custom that’s in their ‘sweet spot,’ per se, but we’re willing to push the envelope and try new things, because it makes us a better company in the long run,” Crook says.

Want to learn more about specing QCP for your next project? Contact our team by emailing us at sales@qcp-corp.com or fill out a form to request a quote, and we’ll connect you with a local sales rep.